Latest Update: Feb 5, 2025, 8:42:06 AM

Greenhouses provide controlled environments for cultivating plants, extending growing seasons, and protecting crops from harsh weather. The success of any greenhouse operation hinges significantly on the materials used in its construction. Choosing the right materials impacts everything from structural integrity and light transmission to insulation, durability, and cost-effectiveness. This article delves into the diverse range of materials employed in greenhouse construction, exploring their properties, advantages, disadvantages, and suitability for various greenhouse designs.

Framing Materials: The Skeleton of Your Greenhouse

The frame provides the structural support for the entire greenhouse. Several materials are commonly used, each with its own set of characteristics:

-

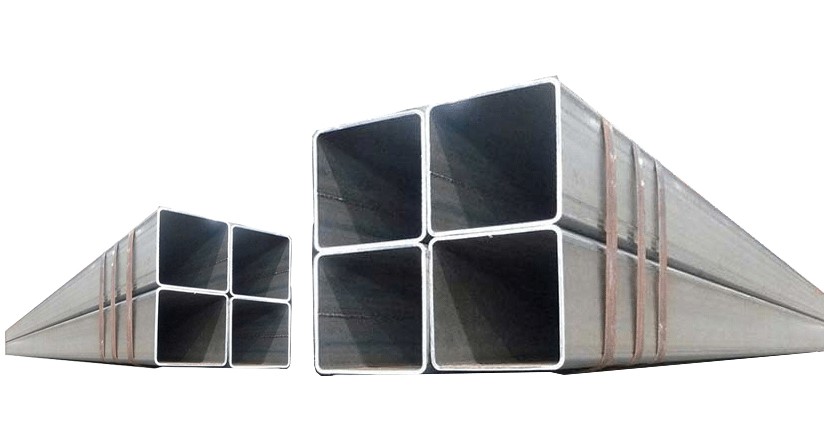

Galvanized Steel: A popular choice for larger, commercial greenhouses, galvanized steel offers excellent strength and durability. The zinc coating protects against rust and corrosion, making it a long-lasting option. However, it can be more expensive than other framing materials. Different gauges and profiles are available, allowing for customization based on the greenhouse's size and load requirements. For greenhouse construction requiring significant structural integrity, galvanized steel is often the preferred material.

-

Aluminum: Lighter than steel, aluminum is also corrosion-resistant and requires less maintenance. It's a good option for smaller greenhouses and hobby structures. While strong, it may not be as robust as steel for larger, heavy-duty applications. Aluminum’s lighter weight makes it easier to work with during greenhouse construction.

-

Wood: Wood offers a more natural aesthetic and can be a cost-effective option, particularly for smaller, DIY greenhouses. However, it is susceptible to rot, decay, and insect infestation, requiring regular treatment and maintenance. Pressure-treated lumber can extend its lifespan. Wood framing is less common in large-scale greenhouse construction due to these limitations.

-

PVC (Polyvinyl Chloride): PVC is a lightweight, affordable plastic material that is resistant to rot and decay. It's often used for smaller, hobby greenhouses and hoop houses. While easy to work with, PVC may not be as strong as steel or aluminum and can become brittle in extreme temperatures. It's a budget-friendly option, but its longevity may be a concern for some.

Dear friends, you can contact Gol Afroos Greenhouse Company for greenhouse services, Spanish Gothic greenhouse construction, Spanish Circular greenhouse construction, Dutch greenhouse construction, and tunnel greenhouse construction. This greenhouse company, with years of activity and experience in agriculture and greenhouse construction, Greenhouse design is with you to provide the best greenhouse services and equipment to your loved ones.

_pX847BG.png)

Glazing Materials: Letting the Light Shine In

The glazing material allows sunlight to reach the plants inside the greenhouse. Transparency, insulation, and durability are key factors to consider.

-

Glass: Traditional greenhouse glazing, glass offers excellent light transmission and clarity. However, it is heavy, fragile, and can be expensive. Tempered glass is more impact-resistant, and laminated glass offers added safety. While aesthetically pleasing and offering superior light penetration, glass requires a robust frame to support its weight.

-

Polycarbonate: A popular alternative to glass, polycarbonate is a strong, lightweight plastic that is highly impact-resistant. It also offers good insulation and diffuses light, which can be beneficial for some plants. Polycarbonate is available in single, double, and multi-wall sheets, with multi-wall options providing better insulation. Its durability and insulating properties make it a common choice in modern greenhouse construction.

-

Polyethylene Film: A cost-effective and flexible plastic film, polyethylene is commonly used for hoop houses and temporary greenhouses. It is lightweight and easy to install, but it has a shorter lifespan than glass or polycarbonate and can tear or puncture easily. UV-stabilized polyethylene films are available to improve their resistance to sunlight degradation. This material is often replaced regularly in commercial greenhouse construction.

-

Acrylic: Similar to polycarbonate, acrylic is a strong, transparent plastic that offers good light transmission and insulation. It is more expensive than polycarbonate but offers superior clarity. Acrylic is less commonly used in greenhouse construction compared to polycarbonate.

Other Essential Materials in Greenhouse Construction

Beyond the frame and glazing, other materials play crucial roles in a functional greenhouse:

-

Foundation Materials: Concrete, gravel, and compacted soil are commonly used for greenhouse foundations. The foundation provides a stable base for the structure and helps prevent soil erosion. The type of foundation will depend on the size and type of greenhouse being constructed.

-

Fasteners and Connectors: Bolts, screws, clips, and other connectors are essential for assembling the greenhouse frame and attaching the glazing. Choosing corrosion-resistant fasteners is crucial for long-term durability.

-

Sealants and Adhesives: Sealants and adhesives are used to create airtight and watertight seals between the frame and glazing, preventing drafts and water leaks. Selecting sealants that are compatible with the chosen materials is essential.

-

Irrigation and Plumbing Supplies: Pipes, valves, and emitters are used for irrigation systems, ensuring that plants receive adequate water. The complexity of the irrigation system will depend on the scale of the greenhouse operation.

-

Ventilation and Cooling Systems: Fans, vents, and cooling pads are used to regulate temperature and humidity inside the greenhouse. These systems are crucial for maintaining optimal growing conditions.

Conclusion

The selection of materials for greenhouse construction is a critical decision that will significantly impact the greenhouse's performance, longevity, and cost. Careful consideration of factors such as structural requirements, light transmission, insulation needs, budget constraints, and environmental conditions is essential. By understanding the properties and characteristics of different materials, greenhouse builders can create structures that are not only functional and efficient but also sustainable and tailored to their specific needs. From the robust framework to the transparent glazing and the intricate systems within, each material contributes to the overall success of greenhouse cultivation, enabling growers to nurture plants in a controlled and optimized environment. Whether it's a small hobby greenhouse or a large-scale commercial operation, the right materials are the foundation for thriving plant life.

The best greenhouse construction company in Tehran

The best greenhouse construction company in Tehran

Greenhouse Irrigation Systems

Greenhouse Irrigation Systems

Greenhouse Heating and Cooling System

Greenhouse Heating and Cooling System

Building a Greenhouse from Scratch

Building a Greenhouse from Scratch

Galvanized can profile 10

Galvanized can profile 10

Axial Fan Evaporative Cooler

Axial Fan Evaporative Cooler

Furnace Heater

Furnace Heater

Type 4 Circulation Fan

Type 4 Circulation Fan

Greenhouse Mist Sprayer

Greenhouse Mist Sprayer